Why We Work in Batches

Closing Reflection

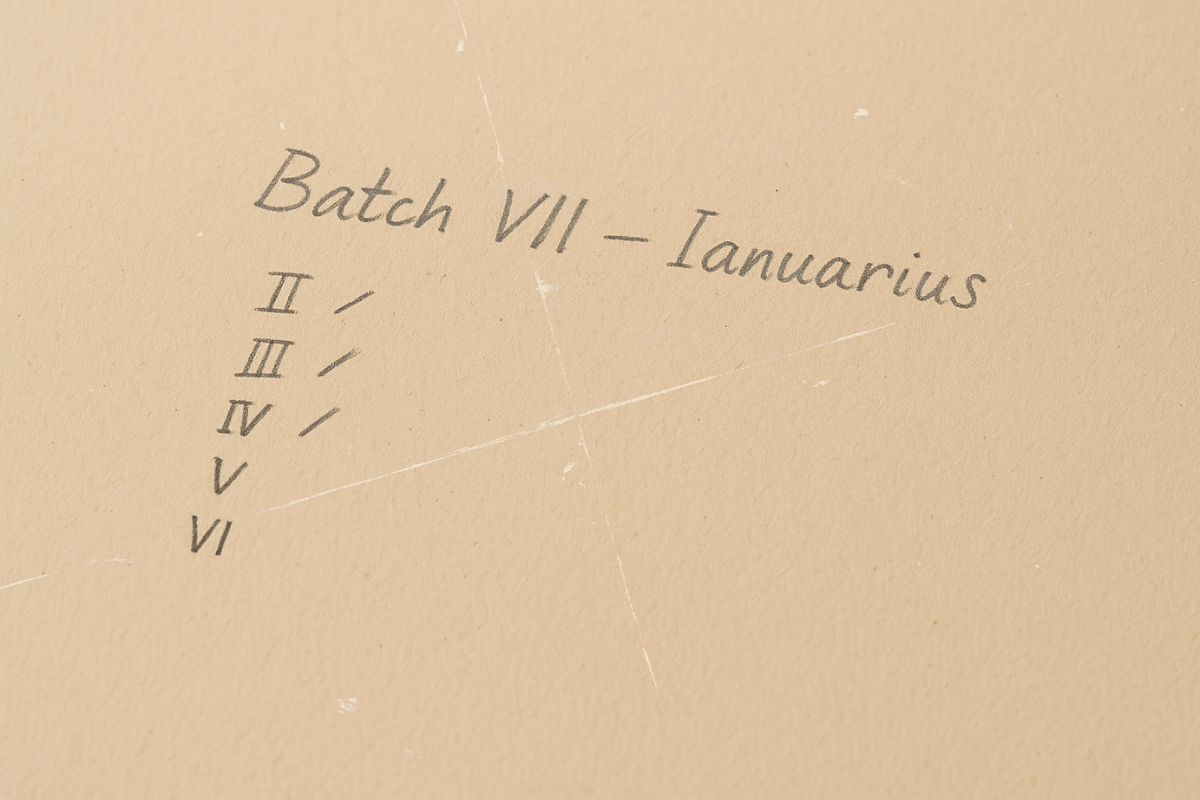

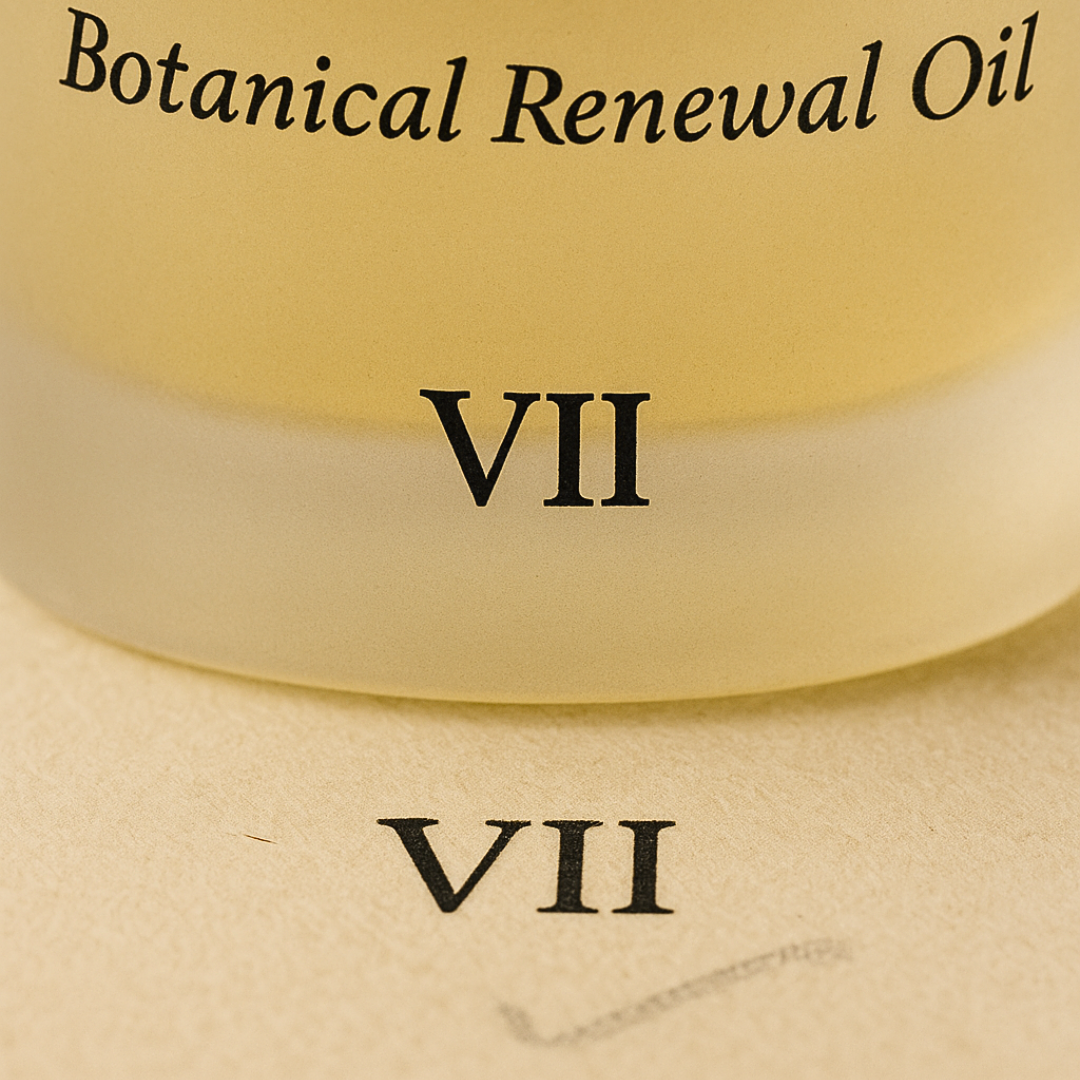

Each batch is an act of restraint — a promise to begin and to end. Rome once sealed its amphorae with wax and clay; we seal ours with date and discipline. Both are signatures of trust. In every bottle of Aurum Lustrum, Sacra Renovatio, or any future treasures of the Domina Collection. That ledger is alive — proof that precision and patience still share a common language.

References

Uses apotheca as storeroom; on seasonal cadence, storage, and household order.

Procedures for pressing, storing oils/wines; separation of lots; record-keeping across seasons.

On freshness, handling, and how time and treatment alter quality.

Provenanced examples catalogued in Pompeii/Ostia; for date/origin/contents on vessels. See:

D.P.S. Peacock & D.F. Williams, Amphorae and the Roman Economy (1986).

Core guidance on batches, batch records, change control, traceability.

December 2025 – Sapientarium Chronicle VI